Accelerated Aging Apparatus

Instrument principle and structure

ApparaTest ZF-DSC-D1X Accelerated Aging Apparatus (AAA) is a thermal analysis instrument that provide a quick way for cables manufacturers as well as cables compounds producers to monitor the quality of cable or raw materials used to ensure compliance with the aging specification requirements of various international standards. ApparaTest ZF-DSC-D1X Accelerated Aging Apparatus (AAA) is a thermal analysis instrument that provide a quick way for cables manufacturers as well as cables compounds producers to monitor the quality of cable or raw materials used to ensure compliance with the aging specification requirements of various international standards.

This instrument is programed to determine the thermal oxidative properties of various materials quite easily and within a short time period. A relationship between the thermal oxidative properties and the long-term stability test can be established by experimental means, using the accepted 7 days aging procedure as the point of reference. This reference will be the basis of comparing the thermal oxidative stability of various samples as measured by AAA. It has the advantage of utilizing a smart processor to operate an analytical software that can be easily installed using a flash drive to any computer running on MS ‘Windows’. The unit is compact in size and is relatively inexpensive.

Instrument Principle and Structure

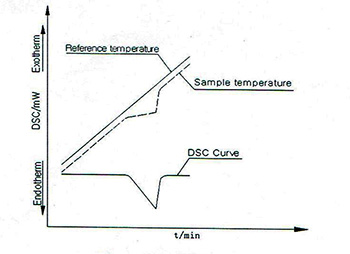

Figure 1 DSC curve

The heart of AAA consists of a technical program of temperature control to measure differentials between the sample material and a reference material with varying temperatures settings.

The AAA consist of a heating furnace, temperature and power detectors, signal converter, dedicated software, data sampling and processing system (computer and printer is optional).

AAA has 2 gas-channels (N2 and 02) that will automatically switch over from one gas inlet to another during the test.

The test will stop automatically when suitable data are acquired for the accurate computing of the Thermal Oxidative Stability result. AAA’s operating principle block-flow diagram is as shown in Figure 1 :-

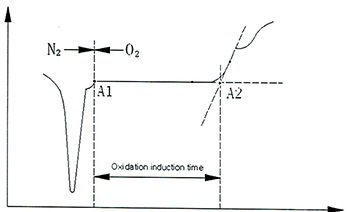

Typical example of experiment with PE

Figure 2

A typical experiment curve is shown in Figure 2:- The sample is first brought to the desired temperature in an inert environment (nitrogen is used). On reaching A1 the equipment will switch over to oxygen, thus starting the oxidative process. During this phase the oxidative action is suppressed by the anti-oxidant present in the sample. The anti-oxidants are continually consumed during this phase. After the depletion of the anti-oxidant, the process undergoes a noticeable exothermic reaction which is expressed in a sudden rise in the power curve. The interest between the steady state and the tangent to the power curve, i.e. point A2 (intersection of biggest

tangent and baseline extension), is automatically deduced. The thermal stability is the measurement of the time from Al to A2 in Minutes.